celebrating national rum month

Award-winning rum blends to sip and savor

A snapshot of the history and complexity of rum through the lens of some of our favorite rum spirits.

DISCOVER YOUR PERFECT RUM

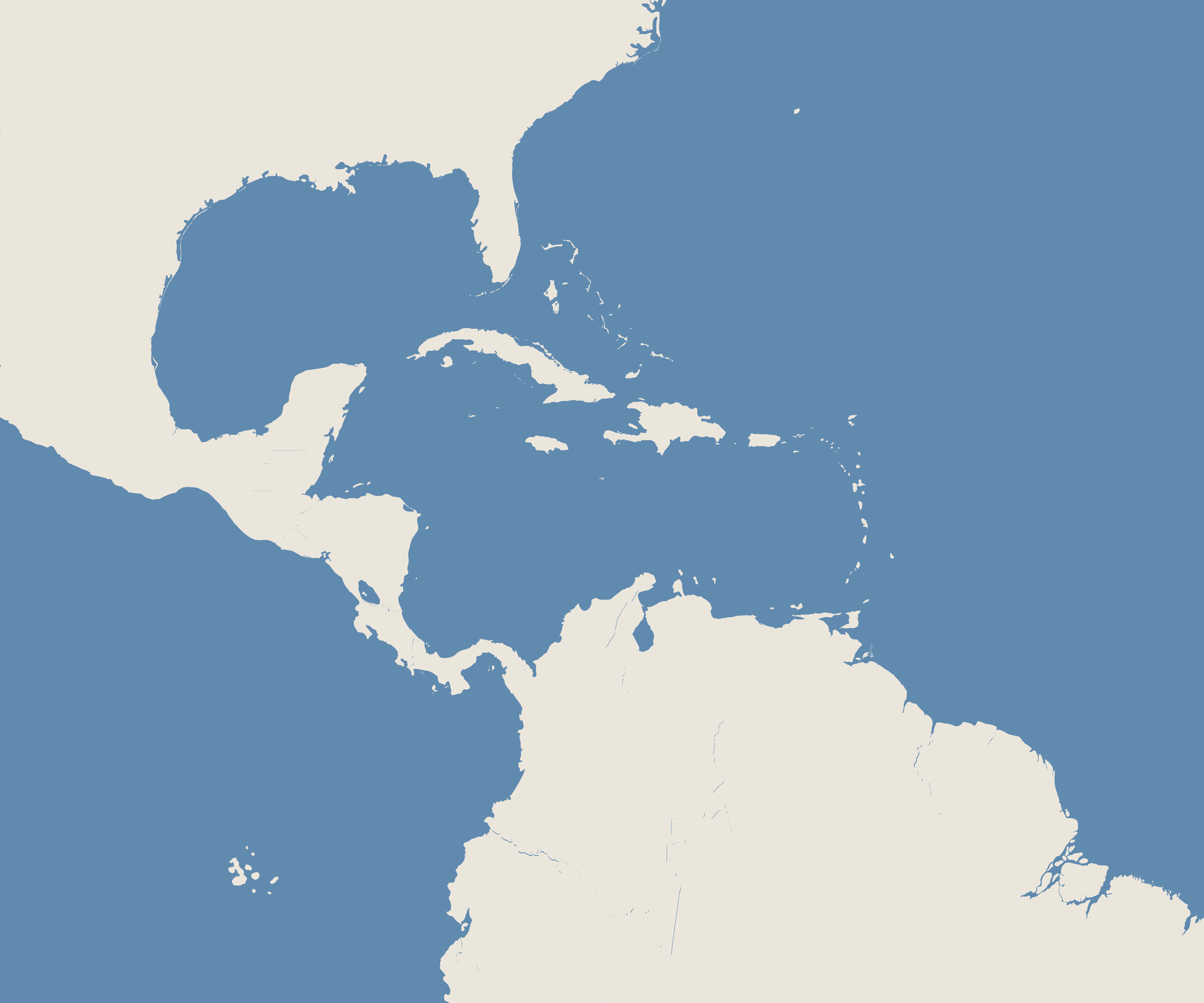

There are several distinct styles of rums blended around the world. Explore the map below to find your favorite and learn more about what makes each style unique.

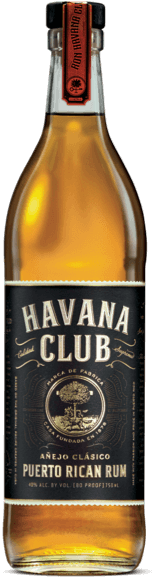

Spanish Style Rums

Spanish is the largest and best-known variety, hailing from rum-famous locations like Puerto Rico, Cuba and Venezuela. It’s derived from molasses and almost always column distilled and filtered with charcoal. Spanish rum is probably the most diverse category, with flavour profiles ranging from light and smooth to dark and sultry

COUNTRIES THAT PRODUCE THIS STYLE OF RUM

Cuba, Puerto Rico, Venezuela, Nicaragua, Guatemala, Panama

English Style Rums

English rum nearly always uses molasses as its base and is distilled in a single pot still. The result is a full-bodied spirit that is dark and rich in color and offers a funkier taste of profile than other rum classifications. Think of English rum as what you’d get in Jamaica, Barbados, or St. Lucia.

COUNTRIES THAT PRODUCE THIS STYLE OF RUM

Jamaica, Anguilla, Barbados, Guyana, Trinidad & Tabago, St. Lucia, Bermuda, Antigua

French Style Rums

If you’ve sipped rum in countries like Martinique and Haiti, then you’re familiar with the French variety. French rum, also called Rhum, is derived from fresh sugar cane juice or even beet sugar rather than cooked syrup or molasses. You’ll find it has a flavor profile that’s grassier and greener than other types.

We can’t leave behind another popular distillate made from the cane juice, cachaça and this one can only be made in Brazil. Cachaça is best known as the base of the Caipirinha cocktail, which is a great way to introduce yourself to the category.

COUNTRIES THAT PRODUCE THIS STYLE OF RUM

Martinique, Haiti

COUNTRIES THAT PRODUCE SUGAR CANE DISTILLATES

Brazil with cachaça

what is rum?

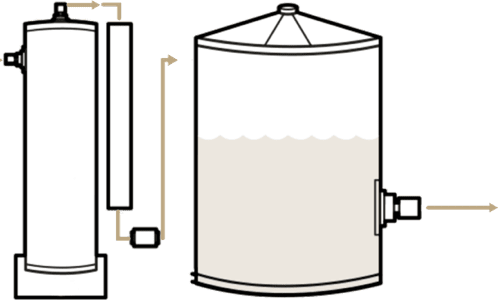

It Begins with sugarcane

Rum is defined as alcohol distilled from sugar. Sounds simple enough, but this centuries-old spirit is actually one of the most complex in the world. Produced using sugar in forms ranging from cane to molasses, the rum category spans so much more than just light and dark. From premium liquor aged for the better part of a decade or more to creative, fruit-flavored infusions, it’s a spirit that’s just as at home in a smoky cigar lounge as it is at a swim-up pool bar.

RUM IS ONE OF THE MOST COMPLEX CENTURIES-OLD SPIRITS IN THE WORLD

background and history

A Smooth

Spirit with a Long Heritage

The first documented rum distillery was built in the Caribbean in the mid-seventeenth century, making it the first spirit in the world to be commercially distilled. From there, the category has continued to expand and diversify, and today, rum is produced in more than 80 countries. It’s classified into three types based on the language spoken in the place where it’s made: English, French and Spanish.

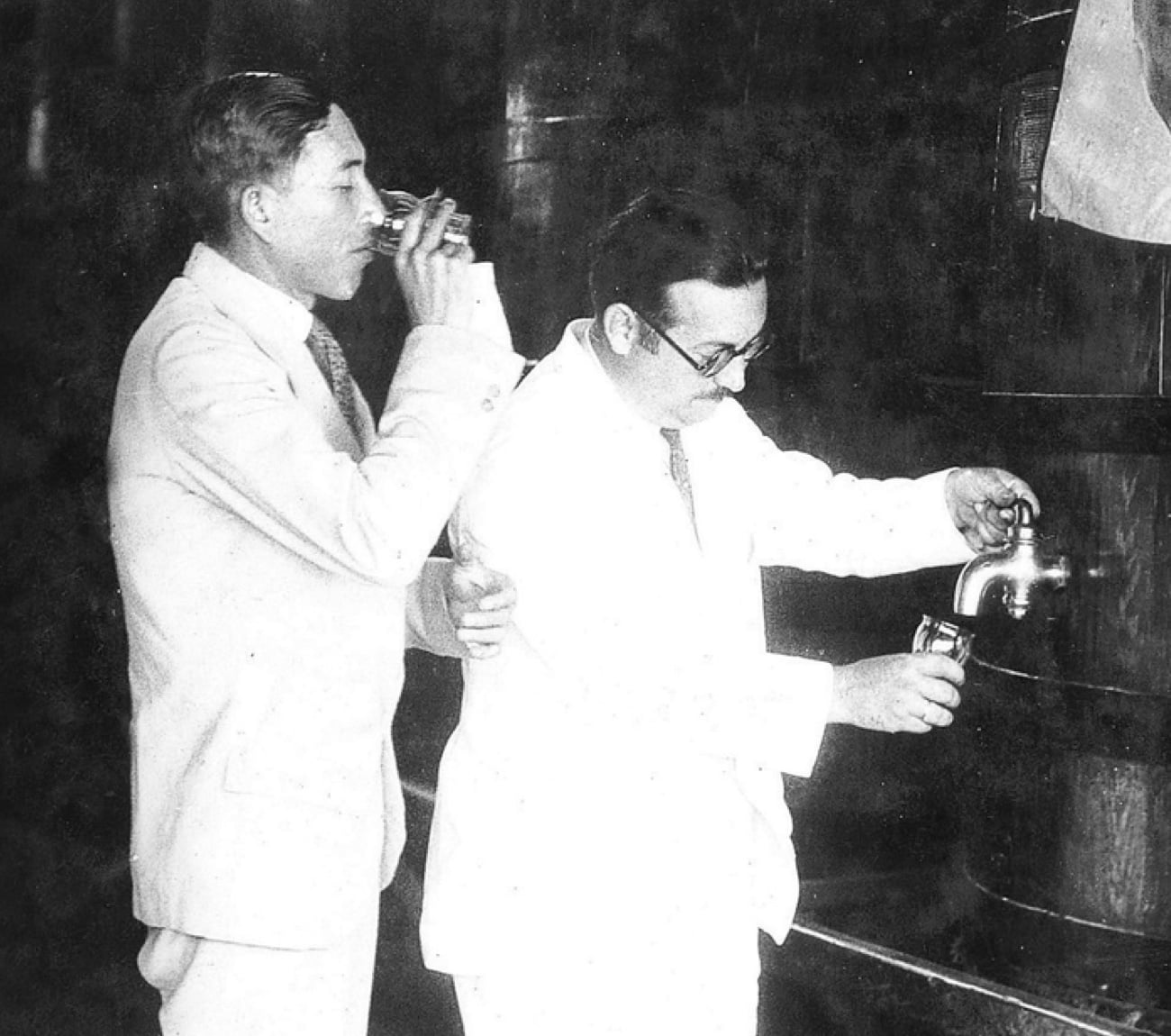

This photo taken at the Bacardi factory, circa 1910